The principle of most LCD liquid crystal displays

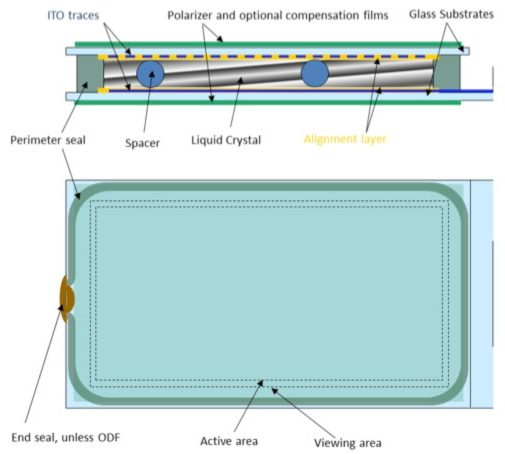

At the most basic level, most (not all) liquid crystal displays change the polarization state of light passing through the layer of liquid crystal material. The competition between the boundary conditions and the applied electric field controls the geometry of the layer. Generally, for this type of liquid crystal display, nematic liquid crystals are applied to the front and rear substrates together with special coatings. The coating is used to create boundary conditions and apply the required electric field. On the outside of the LCD unit, an optical film (including a polarizer) is attached. They convert light polarization changes into light and dark contrasts. The display structure is assembled in such a way that the zero external field produces an extreme brightness state, and the complete external field produces another extreme brightness state. The middle field creates the middle brightness level.

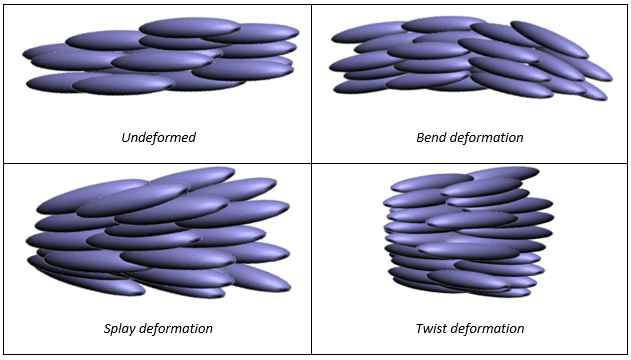

The most common material used to impose boundary conditions is called polyimide. The solution (or precursor) of polyimide is deposited on the substrate and cured. The type of polyimide and the type of liquid crystal determine the angle of the liquid crystal molecules at the contact point between the polyimide and the liquid crystal. If the materials are "similar," the liquid crystal molecules are flat. If they are different (like oil and water), the liquid crystal molecules will stand upright. "Molecular engineering" is used to achieve the ideal application angle, which is different for different types of displays. In order to determine the direction of orientation, the polyimide surface is rubbed or brushed in one direction. The liquid crystal molecules are aligned parallel to the rubbing direction. If the angle and the rubbing direction do not match on the two alignment surfaces, the alignment of the liquid crystal will be elastically deformed. The nematic liquid crystal molecules are expected to be parallel to each other, but if the rubbing directions on the two surfaces are orthogonal, the liquid crystal molecules are forced to twist slightly from one molecule to the other until they pass through the entire layer and the direction is rotated by 90°. Nematic liquid crystals have three main modes of deformation. Each has its own spring constant (spring constant). Depending on the molecular structure of the liquid crystal, some deformation may require more or less force. These three main deformations are called "spreading", "bending" and "twisting".

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.

A complete guide to LCD display connection methods, including SPI, I2C, RGB, MIPI, LVDS interfaces and physical mounting options. Learn how to connect monochrome and TFT LCDs to your development board or product housing.

This week, we had the pleasure of hosting an esteemed international client at our LCD display manufacturing facility in Dongguan. Guided by our team, the client visited key production areas such as the fully automated COG bonding line, backlight assembly area, full lamination workshop, and final product aging test section. They highly appreciated our production capacity, strict quality control, and engineering expertise. This visit strengthened mutual trust and set the stage for future collabora