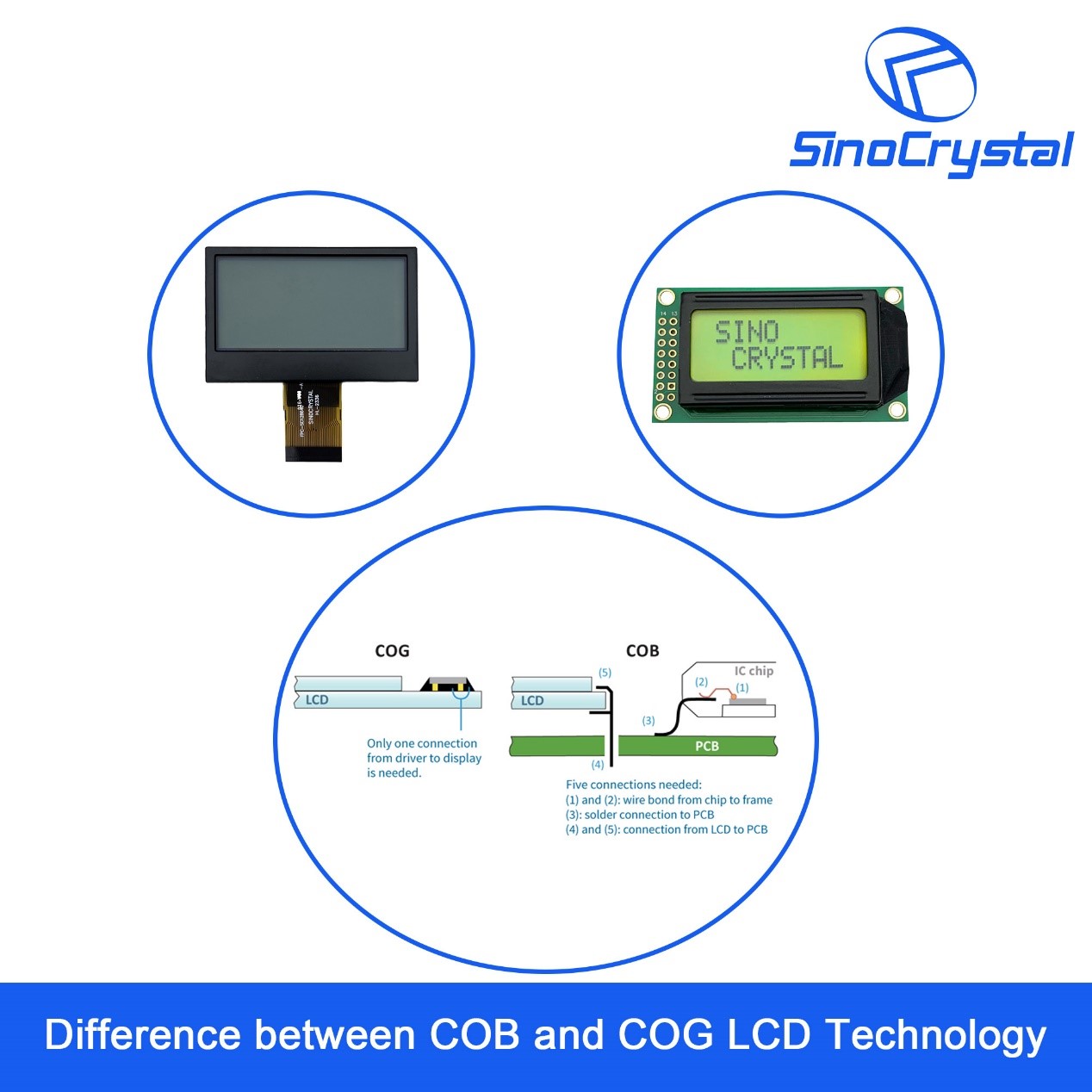

When customer need to custom LCD dot-matrix displays, COB (Chip On Board) and COG (Chip On Glass) are two common packaging technologies. Each offers unique advantages in terms of display performance, cost, reliability, and applicable scenarios. So how do you choose the right packaging method based on your actual needs? This article provides a comprehensive comparison to guide your decision.

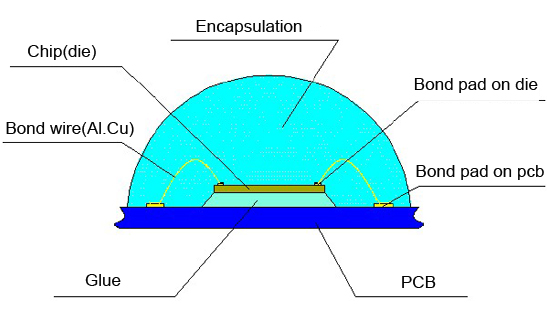

COB involves mounting the driver IC directly onto the PCB. This method is typically used in small-size lcd display, cost-sensitive LCD displays. With a high level of integration and a simple structure, COB is ideal for products that do not require high display performance but prioritize cost efficiency.

Advantages:

High integration reduces circuit complexity

Cost-effective and suitable for mass production

Ideal for small lcd displays such as portable devices and electronic instruments

Disadvantages:

Limited heat dissipation, not suitable for large or high-resolution lcd displays

May not meet high-performance requirements

Typical Applications:

Small-sized lcd display, low-power lcd displays such as smart watches, handheld devices, and simple meters

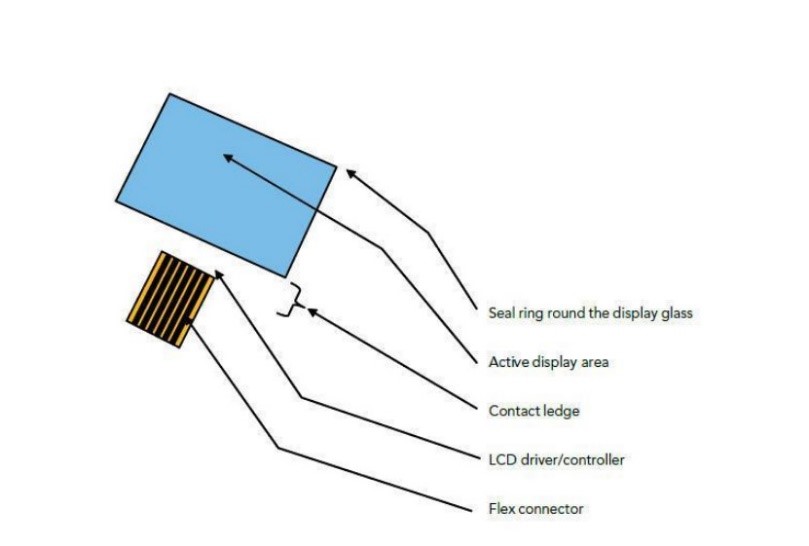

COG involves mounting the driver IC directly onto the LCD glass substrate. It is commonly used for displays requiring higher resolution and better image quality. With improved thermal performance and excellent integration, COG is well-suited for medium to large-sized LCD modules, especially in automotive, industrial, and high-end applications.

Advantages:

High integration by mounting IC directly onto the glass substrate

Excellent heat dissipation, suitable for large and high-resolution displays

Supports high-end display requirements with superior image quality

Disadvantages:

Higher cost, more suitable for high-end products with larger budgets

Longer production cycle and more complex manufacturing process

Typical Applications:

Medium to large-sized lcd displays such as automotive dashboards, medical equipment, and industrial control systems

Choosing between COB and COG depends on several key factors: lcd display size, cost, performance, and the target application.

For small-size lcd display screens:

COB is ideal for compact, low-power devices due to its cost-effectiveness and high integration.

For medium to large-size, high-resolution lcd displays:

COG offers better display performance and heat management, making it the optimal solution for advanced applications.

COB is a great choice for small devices that prioritize cost and do not require high-end visuals.

COG is recommended for applications demanding higher performance, resolution, and reliability.

By evaluating your product needs, selecting the appropriate packaging technology can significantly enhance display performance, reduce costs, and improve the overall user experience.

Sinocrystaloffers customize LCD display packaging solutions to help customers choose the best-fit technology based on their specific requirements—ensuring excellent performance and long-term reliability for every lcd display module.

The 8 inch displays might be affected and delay for an accident.

This is the project management of how sinocrystal handle your customized project relate to displays.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

A complete guide to LCD display connection methods, including SPI, I2C, RGB, MIPI, LVDS interfaces and physical mounting options. Learn how to connect monochrome and TFT LCDs to your development board or product housing.

This week, we had the pleasure of hosting an esteemed international client at our LCD display manufacturing facility in Dongguan. Guided by our team, the client visited key production areas such as the fully automated COG bonding line, backlight assembly area, full lamination workshop, and final product aging test section. They highly appreciated our production capacity, strict quality control, and engineering expertise. This visit strengthened mutual trust and set the stage for future collabora

The ILI9881C is a high-performance a-Si TFT LCD single-chip driver developed by ILI Technology Corp. With its excellent display performance and flexible configuration options, this driver meets the modern display device requirements for high resolution and color accuracy. This article will detail the supported resolutions, interfaces, and power supply voltage of the ILI9881C.

The GC9307, a TFT LCD driver with QVGA resolution, has gained widespread use among LCD module manufacturers since its launch. Sinocrystal are excited to share a series of practical insights we have gathered from using the GC9307 driver.