1. Material Composition and Basic Structure

Adhesive-Based Substrates

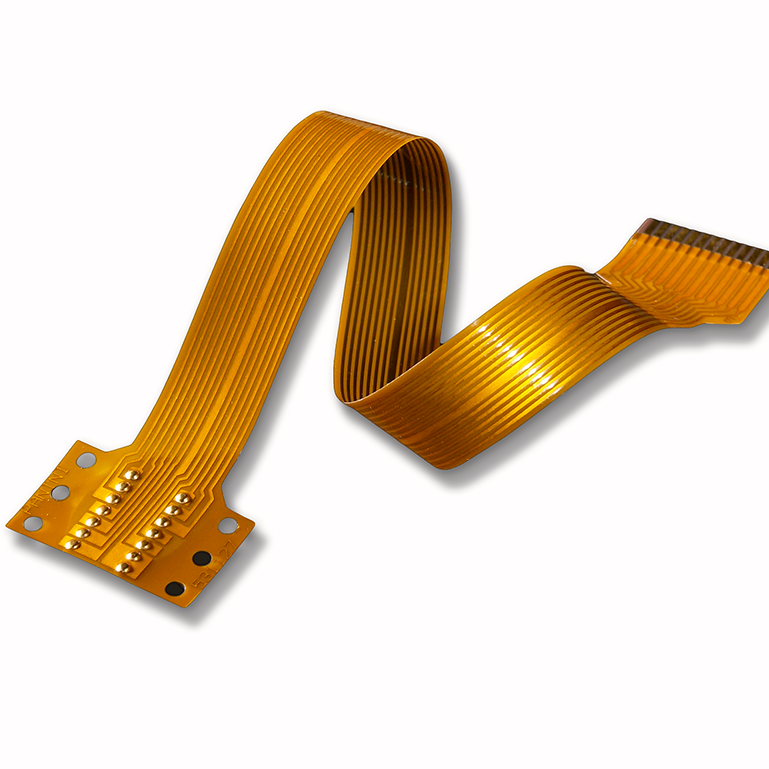

Adhesive-based flexible printed circuit (FPC) substrates consist of three layers: copper foil, adhesive, and insulating film. The adhesive layer is sandwiched between the copper foil and insulating film, ensuring a strong bond between the two. This three-layer structure provides a solid foundation for circuit fabrication by securely attaching the copper foil to the insulating film.

Adhesive-Free Substrates

Adhesive-free FPC substrates directly laminate copper foil and insulating film without using any intermediate adhesive. Through specialized processes like thermal pressing, the copper foil and insulating film achieve a tight bond. This design simplifies the structure and makes adhesive-free substrates suitable for applications requiring higher performance.

2. Functional Characteristics Analysis

Flexibility Comparison

For adhesive-based substrates, flexibility is limited by the properties of the adhesive. Although high-quality adhesives can enhance overall flexibility, repeated bending may cause minor deformations in the adhesive layer, potentially weakening the bond between the copper foil and insulating film over time, leading to delamination.

In contrast, adhesive-free substrates excel in flexibility due to the absence of adhesive constraints. They are ideal for applications requiring extreme bending, such as foldable smartphones, where they minimize the risk of circuit damage from repeated flexing.

Electrical Performance

The electrical performance of adhesive-based substrates is influenced by the dielectric properties of the adhesive. A higher dielectric constant may cause signal delay or attenuation, while low insulation resistance in the adhesive increases the risk of short circuits.

Adhesive-free substrates offer more stable electrical performance, as their insulation resistance and dielectric constant depend solely on the insulating film. This ensures a cleaner signal transmission environment, making them suitable for high-frequency and high-speed signal applications.

Thermal Performance

The heat resistance of the adhesive determines the thermal performance of adhesive-based substrates. At high temperatures, adhesives may soften or flow, compromising the stability and reliability of the FPC.

Adhesive-free substrates, lacking adhesive layers, exhibit superior dimensional stability and consistent physical/electrical performance under temperature fluctuations. This makes them ideal for high-temperature environments, such as automotive electronics.

Thickness and Dimensional Precision

The thickness precision of adhesive-based substrates is limited by the uniformity of the adhesive layer, making it challenging to meet ultra-thin FPC requirements.

Adhesive-free substrates, without an adhesive layer, enable precise thickness control, fulfilling the demands of high-precision circuit manufacturing.

3. Production Process Considerations

When processing adhesive-based substrates, attention must be paid to adhesive curing and the impact of etching solutions on the adhesive. For adhesive-free substrates, the focus shifts to achieving flawless lamination between the copper foil and insulating film, ensuring optimal bonding while simplifying etching and other manufacturing steps.

4. Practical Applications

Adhesive-based substrates are commonly used in cost-sensitive, low-performance electronics like electronic toys and basic calculators.

Adhesive-free substrates are widely applied in high-end devices demanding exceptional flexibility, electrical performance, and thermal stability, including aerospace equipment, advanced medical devices, and cutting-edge communication systems.

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.

A complete guide to LCD display connection methods, including SPI, I2C, RGB, MIPI, LVDS interfaces and physical mounting options. Learn how to connect monochrome and TFT LCDs to your development board or product housing.

This week, we had the pleasure of hosting an esteemed international client at our LCD display manufacturing facility in Dongguan. Guided by our team, the client visited key production areas such as the fully automated COG bonding line, backlight assembly area, full lamination workshop, and final product aging test section. They highly appreciated our production capacity, strict quality control, and engineering expertise. This visit strengthened mutual trust and set the stage for future collabora