The thinning of the display glass substrateis mainly to use chemical etching and physical polishing to thin the panel and display glass to meet the needs of light and thin display products. The following panel application requirements can be achieved by thinning the 3.5 inch tft display panel .

1. Use chemical or physical methods to reduce the thickness of the glass substrateis to achieve the purpose of thinning the panel.

2. Reduce the weight of the display screen; provide a clearer and brighter picture quality.

3. Reduce the occupied space, reduce the thickness of the module, and leave more space, such as increasing the battery capacity.

4. Make the glass substrate to a certain degree of flexibility, produce curved screens, and increase better visual effects.

TFT LCD Glass Substrate Thinning Process

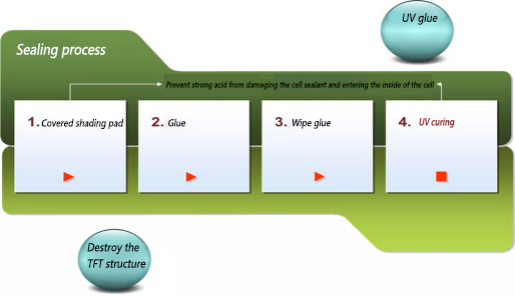

1. Sealing process

Prevent the acid-base solution from entering the liquid crystal cell from the edge, destroying the frame sealant, entering the cell, and affecting product performance.

2. Etching and thinning process

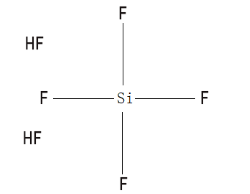

Thinning principle method: 6HF+SiO2->H2SiF6+2H2O liquid+solid (glass)->liquid

Thinning method:

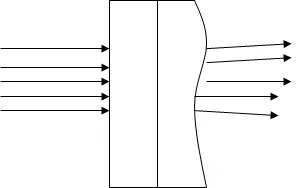

1. Multi-piece upright immersion type

Advantages: multiple pieces of glass can be processed at the same time.

Disadvantages: The device is large. There are sediments and white powder on the periphery, which are easy to adhere to the glass.

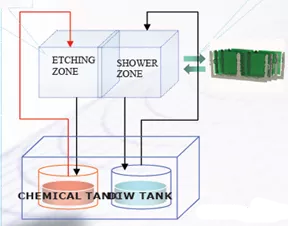

2. Single piece upright spray type

Advantages: It can meet different etching requirements on both sides. Multi-piece

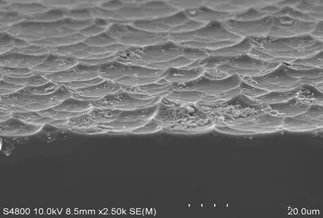

Disadvantages: pits are easily generated on the etched surface.

3. Waterfall

Advantages: the surface is the smoothest, even without polishing

Main components of thinning process and equipment:

Process: Loader---Pre-cleaning---Etching---Cleaning---Drying---Unloader0.96 mono oled display equipment components: acid supply device, HF acid concentration meter, temperature controller, gas scrubber

Thinning process parameters

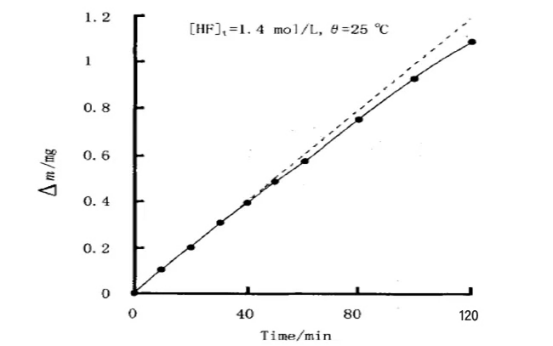

1. The relationship between reaction time and glass quality loss

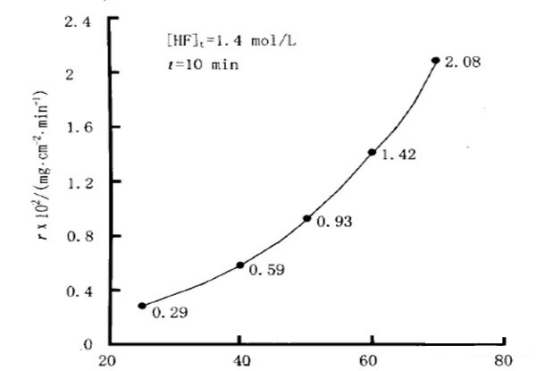

2. The relationship between reaction rate and reaction temperature

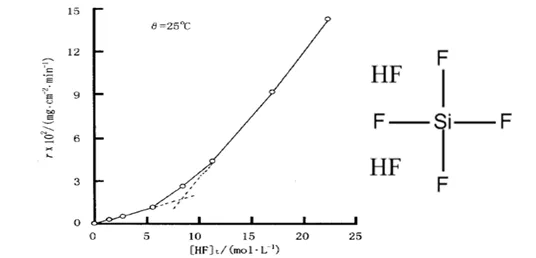

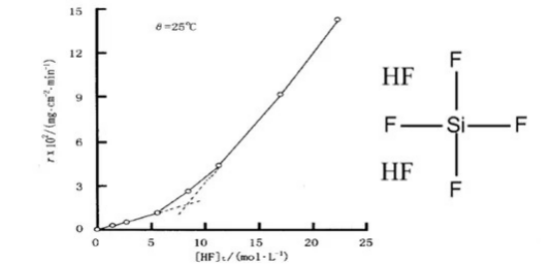

3. The relationship between reaction rate and HF acid concentration

Explanation: (HF)2 is the most important active component in HF acid solution, because H-F bonds in the form of hydrogen bonds are more fragile than H-F bonds in HF molecules, and are easier to break when reacting with SiO2.

3. Grinding process

Process flow:

Poor thinning process itself

1. Do not wipe the dirt

2. Uneven thinning

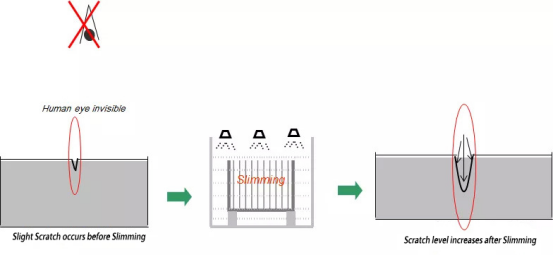

3. Scratch after slimming

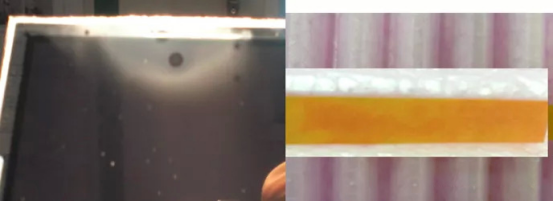

4. Poor B-ITO

Phenomenon: After the B-ITO of the ADS product is finished, the ITO in the contact position of the product and the BOX is severely corroded, which is similar to the mark left on the surface of the product after the water is dried.

Reason: BOX has a long-term turnover in the slimming workshop, and the acid gas in the slimming workshop has adhered to the surface of the BOX for a long time, which makes the surface of the BOX appear acidic.

5. Excessive resistance

Reason: acid residue

Sexual tolerance related to thinning

1. Shock and drop: Shock and drop the LCM. Perform display inspection and visual inspection on LCM.

2. Confirmation of the etching status of the glass substrate surface: Put it into a hot and cold tank with alternating hot and cold for display inspection of LCM and glass appearance inspection of TFT for microscope.

3. Confirmation of the corrosion status of the TFT terminal: continuous aging in a high-temperature and high-humidity aging tank. SEM observation and analysis of the surface and cross-section of the TFT terminal.

The 8 inch displays might be affected and delay for an accident.

New iPhone 13 Series will use On-Cell OLED Displays. And it that will be launched in the second half of this year will be exclusively supplied by Samsung Display (SDC)

This is the project management of how sinocrystal handle your customized project relate to displays.

Discover how LCD displays are evolving in industrial automation — from high-brightness and rugged designs to smart connectivity and energy efficiency. Explore what’s next for industrial-grade visual interfaces.

Discover the key factors to consider when choosing an LCD display for your project, including size, resolution, interface, brightness, and customization options from a factory-direct manufacturer.

Discover the latest innovations in rugged LCD displays for harsh environments — from extreme temperature resistance to sunlight readability and waterproof designs. Factory-direct manufacturing with full customization.

A complete guide to LCD display connection methods, including SPI, I2C, RGB, MIPI, LVDS interfaces and physical mounting options. Learn how to connect monochrome and TFT LCDs to your development board or product housing.